Double-Sided Wafer Locks for Antique Cars

Better Security for the Masses

Early Briggs & Stratton switch with King lock

|

The lock plug from the switch at left. The pair of scratch marks across the wafers were probably from the factory.

|

Three different materials were used for the wafers, each being of a different thickness, probably to control end play. |

||

The keys for this ignition switch are marked Basco |

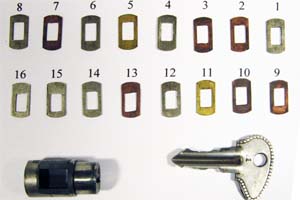

This later version contains twenty wafers of uniform thickness. There are no springs in this lock or the one above. |

Besides the use of wafers in their new lock design, King locks departed from another industry standard. Pin-tumbler locks were designed with separate, distinct, and equally spaced cuts so that with the key inserted, the pins rested at the bottom of the cuts; because the King double-sided key used a gradual undulating curve and the wafers were presented as a "pack", each individual wafer could come to rest at a low spot, a high spot, or somewhere in between. Lock design for double-sided wafer locks eventually diverted, with some maintaining the undulating keys and associated wafer packs while others used discrete depths and spaces for their keys such as used with pin-tumbler locks. | ||

| Briggs & Stratton switches as above were the first to use the new wafer lock as early as 1915 for Chevrolet. When Ford began using them for the electric start Model T in 1919, the locks used distinct depths and spaces. | ||||

Clum Manufacturing was another early provider of double-bitted wafer locks. The cross section of the Clum key looks very much like that of the King key. An outstanding feature of the Clum key is the patent date shown on the reverse, August 15, 1916. While a Clum patent of that date exists, examination of the patent contains no mention of either the key or the associated lock. There was a patent submitted later that year that discussed the lock, but not actually issued until years later. |

|

|||